YDK120-120-4 / YYF120-120-4

CPMDJ

| Availability: | |

|---|---|

| Quantity: | |

Product Description

1. NSK low noise high quality rolling bearing.

2. Brass terminals plug-in.

3. Shaft: single shaft, nickel plating treatment.

4. Enclosure: electrophoretic coating treatment.

5. Winding: 100% pure copper.

1. Steel housing, designed for cooling system, evaporative cooler etc, suit for hot weather environments.

2. High quality winding with excellent insulation and heat transmission properties.

3. Nice appearance, high starting torque, low starting current, smooth turning, low temperature rise, low vibration, low noise and great overload performance.

4. Saving Energy, higher efficiency.

5. Long life, Equipped with overheating protection, good Protection against Humidity.

At Changpeng Motor, you always have a personal contact who will be happy to advise you and answer your questions about the best electric fan motor solution for your application - quickly and competently. High-quality technical production and processing systems and the handling of qualified, experienced engineers and skilled workers guarantee you the highest motor standards. Additionally, all of our AC fan motors and EC motors comply with current ISO standards.

| Model | Voltag e(V) | Frequency (Hz) | Output (W) | Speed (RPM) | Capacitor (μF) | Rotation | Insulation Class |

| YDK140-150-6T5 | 220-240 | 50 | 1/5HP | 850/3 SPD | 10 | CCW | B |

| YDK160-185-4A | 115/127 | 50/60 | 1/4HP | 1425/1725 | 10 | CW-SE | B |

| YDK160-185-4A2 | 220/230 | 50/60 | 1/4HP | 1425/1725 | 10 | CW-SE | B |

| YDK160-245-4A | 115/127 | 50/60 | 1/3HP | 1425/1725 | 10 | CW-SE | B |

| YDK160-245-4A2 | 220/230 | 50/60 | 1/3HP | 1425/1725 | 15 | CW-SE | B |

| YDK160-375-4A | 115/127 | 50/60 | 1/2HP | 1425/1725 | 15 | CW-SE | B |

| YDK160-375-4A2 | 220/230 | 50/60 | 1/2HP | 1425/1725 | 20 | CW-SE | B |

| YDK160-550-4A | 115/127 | 50/60 | 3/4HP | 1425/1725 | 20 | CW-SE | B |

| YDK160-550-4A2 | 220/230 | 50/60 | 3/4HP | 1425/1725 | 20 | CW-SE | B |

| YDK160-735-4A | 115/127 | 50/60 | 1HP | 1425/1725 | 30 | CW-SE | B |

| YDK160-735-4A2 | 220/230 | 50/60 | 1HP | 1425/1725 | 30 | CW-SE | B |

| YDK120-120-4 | 220/240 | 50/60 | 120 | 1350 | 5 | CW-SE | B |

| YDK139-150-6 | 208-230 | 50/60 | 150 | 930 | 10 | CW-SE | B |

| YDK139-200-4 | 208-230 | 50/60 | 200 | 1180 | 10 | CW-SE | B |

| YDK139-350-4 | 208-230 | 50/60 | 350 | 930 | 12 | CW-SE | B |

| YSK139-350-4 | 208-230 | 50/60 | 350 | 1200 | 10 | CW-SE | B |

| YDK139-100-10 | 208-230 | 50/60 | 100 | 520 | 6 | CW-SE | B |

| YDK139-150-4 | 208-230 | 50/60 | 100 | 1100 | 6 | CW-SE | B |

Fan Motor Manufacturers

As a leading fan motor manufacturer, we put our customers, their individual requirements and the quality of fan motors at the heart of our daily work.

Changpeng Motors has been producing fan motors since 2005. Many industrial equipment operators and global fan motor wholesalers, suppliers, distributors and shop owners from the HVAC industry trust the proven quality of CPMDJ fan motors. We cast millions of stators and rotors and work with companies of all sizes. In addition, Changpeng Motors has also opened a centrifugal fan factory in 2019.

It takes a lot of manual work, skill and years of experience to offer such a wide range of cooler fan motors. In addition, Changpeng Motors has dipping equipment and drying kilns with shaft heights up to 800 mm, an in-house welding shop for flexible production of special components and custom welding designs, VPI dipping equipment and experienced specialists who truly understand their processes. This is how we guarantee the high quality, reliability and durability of our air cooler fan motors.

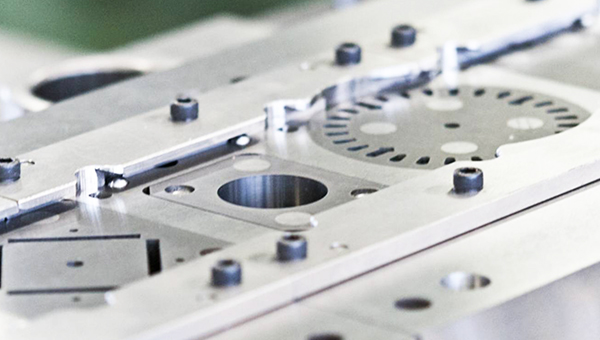

1. STATOR CORE & ROTOR COREStator core and rotor core for fan motor from air cooler motor manufacturers are built up of thin punched laminations of Silicon Steel, its stator laminations and rotor laminations are made by high speed punch machine which is invested by our own, and this plays a vital role in quality of ac fan motor. Over 10 Million press strokes per day allows output of over 100 Tons finished stator / rotor core laminations each day. |  |

| 2. COIL WINDINGProfessional in the evaporative air cooler fan motor technology, team from air cooler motor manufacturers has extensive experience working with both copper and aluminium wire in various forms to provide coil winding solutions. Our broad customer base demands that we cannot only supply our standard range of swamp air cooler fan motor but also have the capability to provide custom solutions to solve challenges others can't. Contact your air cooler motor manufacturers now! |

3. STATOR ASSEMBLYChangpeng Motor, air cooler motor manufacturers / air cooler motor suppliers, has specialized in the fan motor technology, stator assembling can be solved by our own professonal assembly technique. It meets the requirements of series production in ac fan motor, condenser fan motor, evaporator fan motor and other fan motor for ac unit. We develop and examine the entire process chain - from slot insulation to impregnating the stator and test. |  |

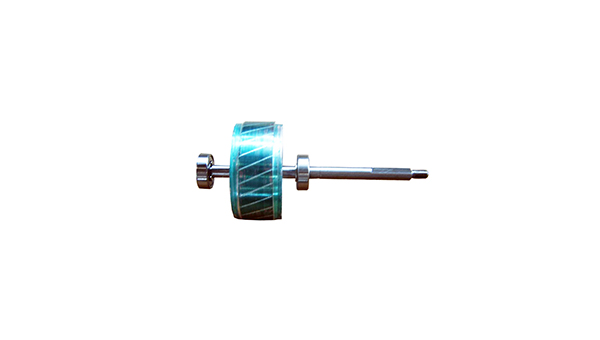

| 4. ROTOR ASSEMBLYRotor assembly is critical to evaporaitve air cooler fan motor in a variety of industries and applications, like condenser, air conditioner, evaporator etc. CPMDJ, air cooler motor manufacturers / air cooler motor suppliers provides high quality silicon steel material to create professional and high quality rotor assembly for all electric fan motors. A rotor assembly of ac fan motor normally includes a cylindrically shaped shaft, a processed rotor iron core and a bearing. |

5. COOLER FAN MOTOR SHAFTMotor shaft is the main component in electric fan motor. The size of the shaft significantly affects the torque in fan motor. In addition to the need to mount the rotor and a variety of attachments, like bearing, the model of the motor shaft is based on the cooling concept selection of the electric device. CPMDJ, air cooler motor manufacturers & air cooler motor suppliers always offer you high quality shaft as evaporative air cooler fan motor parts/swamp air cooler fan motor parts. |  |

| 6. COOLER MOTOR ASSEMBLY & TESTINGMotor assembly includes assembling stator assembly, rotor assembly and end cover assembly with front cover. Testing of air cooler fan motor from air cooler motor suppliers,Changpeng Motor, cover the whole areas from stator insulation test, electronic integrated test bench for winding inserting, motor integrated test bench, motor performance test, noise test and appearance detection through to dynamometer for high performance fan motor testing. |

As a manufacturer of AC fan motors, including air cooler motors, air conditioner fan motors, indoor fan motors, outdoor fan motors, window AC fan motors, condenser fan motors, general purpose fan motors, fan coil motors, heat pump fan motors, resin Packing motors, EC fan motors, AC centrifugal fans and EC centrifugal fans, we quickly and reliably meet your custom requirements. You can always rely on the proven CPMDJ quality. High-quality technical production and processing plants, as well as the handling of qualified and experienced engineers and specialists ensure the highest standards of air cooler motors. To maintain quality standards, Changpeng Motors has introduced a quality management system.

Needless to say, our cooling fan motors meet the requirements of international standards and state-of-the-art technology. This is how we ensure global use and durability of evaporative cooler fan motors.

Be Agency of Fan Motor Factory

As a prominent and leading fan motor manufacturers & suppliers in China, Changpeng motor is willing to open worldwide market by agency. Be our agency, you can extend your business fast for your fan motors at the competitive price, stable qualtity and excellent after service. Contact your ac fan motor factory now to get hvac fan motor price Now!

Air Cooler Motor Test & Applications

As a independent medium-sized company, we carry out routine testing and type tests on all fan motors of single phase and three phase machines for you - with the utmost care and quality. This means that our test facility is used for the routine testing of all customer's orders of fan motors.

Visual inspection

Resistance measurement of stator winding at ambient temperature

Insulation resistance measurement of stator winding and accessories

High-voltage check of stator winding

Rotational direction check

No-load check at rated voltage

Short-circuit test at partial voltage

Check of fan motor accessories

Measurement of ripple voltage at rated voltage, rated frequency, and no-load speed

Creation of test report

In addition, the following optional tests are possible for asynchronous fan motors:

Measurement of no-load characteristic (recording of no-load current and no-load power at differing voltage)

Measurement of short circuit characteristic (recording of short circuit current and short circuit power at differing voltage)

Determination of polarization index of stator winding

Noise measurement (only at no load)

Type testing of asynchronous fan motors, with heat run

Visual inspection

Resistance measurement of stator winding at ambient temperature

Insulation resistance measurement of stator winding and accessories

High-voltage check of stator winding

Rotational direction check

No-load check at partial voltage

Heating test under load

Measurement of load characteristic (25%, 50%, 75%, 100%, and 125% load)

Bearing heating check at no load and rated speed (only for friction-type bearing machines)

Check of fan motor accessories

Measurement of ripple voltage at rated voltage, rated frequency, and no-load speed

Creation of test report

In addition, the following optional tests are possible for asynchronous fan motors:

Measurement of no-load characteristic (recording of no-load current and no-load power at differing voltage)

Measurement of short circuit characteristic (recording of short circuit current and short circuit power at differing voltage)

Determination of polarization index of stator winding

Noise measurement (only at no load)

System/routine/type test of asynchronous fan motors

Changpeng Motor offers a complete line of HVAC motors designed to operate in the harshest applications while reducing total cost of ownership. Our fan motors can be used in a variety of applications including air cooler fan motors, air conditioner fan motors, indoor fan motors, outdoor fan motors, window AC fan motors, condenser fan motors, general purpose fan motors, fan coil motors, heat pump fan motors , resin encapsulated motors and EC fan motors. We can also customize any fan motor version for specialized HVAC applications.

1. Cooler fan motor from Changpeng Motor, the fan motor manufacturers & suppliers, can be applied in various kinds of air coolers, evaporative air coolers, desert air coolers and swamp coolers, commercial and residential.

2. Air conditioning system.

Service from Fan Motor Suppliers

As a fan motor factory & manufacturer for HVAC applications, Changpeng Motor offers our customers further important plus points except focusing on fan motor quality. One of our focal points is the fast delivery of fan motor orders - including special designs. Not many fan motor manufacturers are able to claim that they can supply brand-new fan motors from their own ranges but also the OEM replacement motor of other brands within just a few days.

Flexible machining from our fan motor manufacturer allows us to achieve exceptional response times. CPMDJ customers around the world appreciate our fast delivery service. Try us out! Team of experts from Changpeng Motor will help you to find the right fan motors for your HVAC application.

CPMDJ provides a 24-hour hotline for our fan motor customers. You can use it to reach us around the clock in the case of a pressing operational disruption. With CPMDJ, you can depend on a fan motor manufacturer who can supply fan motors with various voltages and outputs even outside normal working hours - all around the world.

There's a lot to consider when it comes to ordering fan motors. The CPMDJ team is here for you. Let us know what you're looking for, and we'll help you determine which fan motor options are best for your application.